Steel strapping is a vital component in the world of packaging and logistics, providing strength, durability, and security for a wide range of applications. Often used in industrial settings, it plays a crucial role in ensuring that products remain intact during transportation and storage. This article will discuss its many types, its uses across different industries, and the benefits it offers.

What is Steel Strapping?

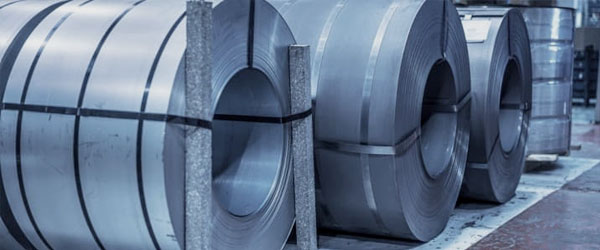

It is a type of banding material made from high-strength steel. It is designed to secure products and materials tightly, preventing movement during transit. Available in various widths and thicknesses, steel strapping can withstand significant tension and is commonly used in heavy-duty applications where other materials, like plastic, may fail.

Types

Regular Duty

Typically used for general applications, this type provides a balance between strength and cost. It is ideal for products like lumber, bricks, and steel coils.

High-Strength

This strapping is engineered for heavy loads and harsh conditions. It is commonly used in industries like construction and heavy manufacturing, where maximum tension and durability are crucial.

Painted and Unpainted

Painted steel lashing often features a protective coating to prevent rust and corrosion, making it suitable for outdoor applications or environments prone to moisture. Unpainted strapping is typically used in indoor settings where moisture exposure is minimal.

Cold Rolled

Manufactured through a cold rolling process, this type offers enhanced flexibility and strength. It is often used in packaging heavy machinery and large industrial components.

Strapping Tools and Accessories

Alongside the strapping itself, various tools and accessories are available, including tensioners, sealers, and clips, to facilitate the strapping process. These tools ensure that the strapping is applied correctly and securely.

Uses of Steel Strapping

It is employed in numerous industries, including:

Manufacturing

In manufacturing, it is essential for bundling products, securing pallets, and stabilizing loads for transportation. It ensures that components remain in place during handling and transit.

Construction

Construction materials, such as bricks, lumber, and steel beams, are often strapped together to create manageable bundles. This prevents shifting and damage during transport to construction sites.

Shipping and Logistics

Steel lashing is widely used in shipping to secure goods within containers, preventing movement that could lead to damage. Its high tensile strength makes it ideal for heavy cargo.

Paper and Textile Industries

In the paper and textile sectors, band steel is used to bundle rolls of paper or fabric. It keeps products secure during storage and transport, maintaining their quality.

Automotive Industry

Band Steel plays a role in securing automotive parts and components during shipping. It ensures that delicate items do not move or get damaged en route to assembly lines.

Benefits of Steel Ties

High Strength and Durability

One of the primary advantages of steel strapping is its exceptional strength. It can withstand significant loads and stress, making it suitable for heavy-duty applications.

Resistance to Environmental Factors

It is resistant to various environmental factors, including moisture and UV exposure, especially when treated with protective coatings. This resistance ensures that it remains reliable in outdoor and harsh environments.

Secure Load Stability

It effectively stabilizes loads, preventing shifting during transit. This stability minimizes the risk of damage to products and reduces the likelihood of accidents during handling.

Cost-Effectiveness

While it may have a higher initial cost compared to plastic alternatives, its durability and reusability can lead to long-term savings. The reduced risk of product damage and loss translates into lower overall costs.

Versatility

It can be used in various applications across multiple industries, making it a versatile choice for companies. Its ability to be used with different types of tools and accessories further enhances its functionality.

Recyclability

Steel is a recyclable material, which contributes to sustainability. Companies can recycle steel, reducing waste and promoting environmentally friendly practices.

Challenges and Considerations

Despite its numerous advantages of using metal strapping, there are challenges associated with strapping with steel. The primary concern is the potential for injury during application. It can be sharp and may cause cuts if mishandled. Proper training and the use of protective equipment are essential when working with It.

Additionally, the equipment required for strapping of steel, such as tensioners and sealers, can be costly. Companies must consider these costs when deciding on the best strapping solution for their needs.

Conclusion

It is an indispensable tool in various industries, offering strength, durability, and reliability. Its ability to secure heavy loads during transportation and storage makes it a preferred choice for manufacturers, shippers, and construction companies alike. While it may come with certain challenges, the benefits of steel ties—such as high strength, resistance to environmental factors, and recyclability—far outweigh the drawbacks.

As industries continue to evolve and the demand for secure packaging solutions grows, steel lashing will remain a cornerstone of safe and effective logistics and manufacturing practices. For businesses seeking a reliable and robust strapping solution, investing in steel can lead to increased efficiency, reduced costs, and enhanced product protection.