In the manufacturing industry, selecting a metal stamping company is important. It can make or break the quality of your products. Not all manufacturers are equally talented. Finding the right progressive die manufacturers is important to complete your project.

The perfect manufacturer meets your specifications. They utilize advanced technology, and are dedicated to customer satisfaction. Here, we will explore the major factors to consider when selecting a progressive die manufacturer.

Determine your requirements.

Finding the right metal stamping company might be quite challenging. If you clearly understand your requirements, the process becomes more manageable and focused. Here is an overview of the key aspects to consider:

Material Type:

Various manufacturers may specialize in different metals. Your project may require stainless steel, aluminum or any other metal. It is important to find a progressive die manufacturer experienced in working with your specific material.

The quality of the metal have a significant impact on your final product. Check that the manufacturer can get and deal with the precise grade you need.

Production Volume:

Always consider your production size. Are you looking for a firm that can manage large-scale production? Else do you require smaller and more personalized batches? Your production volume will influence your decision.

Some manufacturers may be better suited for mass production. For custom projects approach manufacturers who specialize in customized projects. Think about future growth. Ask yourself if the manufacturer can raise output if your demand rises.

Design Specifications:

Some designs may be complicated, necessitating extensive tools and experience. Ensure that the manufacturer can handle the complexity of your design.

Precision is essential in progressive die manufacturing. Define the acceptances you require, and check that the manufacturer can regularly meet them.

Delivery Expectations:

Consider your delivery expectations. How soon do you need the products? Some manufacturers may offer quicker lead times due to efficient processes or closeness to your site.

Consider the logistics of shipping stamped products. Does the manufacturer provide delivery services, or will you have to organize transportation?

Look for Customized solutions.

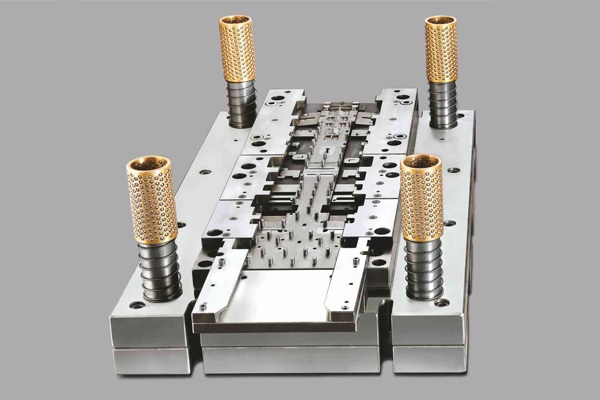

Choosing the appropriate stamping die maker is an important step. This ensures the success of your metal stamping project. The quality and precision of the stamping die have a direct impact on the final product. This only ensures the quality and manufacturing efficiency of the final product.

A reputable stamping die manufacturer will provide tooling solutions. These are customized to meet your individual manufacturing requirements. Whether you need progressive dies, transfer dies, or single-station dies, the manufacturer should be able to deliver the appropriate solution.

Collaboration and testing

A collaborative design approach that incorporates feedback and input from your team might result in a more efficient and effective tooling solution.

Before finishing the design, the manufacturer should run simulations and tests to detect potential problems and optimize the design for maximum performance.

Summing up

By identifying your unique requirements ahead of time, you may narrow your search and select a progressive die manufacturer who meets your exact specifications. This proactive strategy saves your time and ensures that you form a productive and amicable connection with the selected manufacturer.