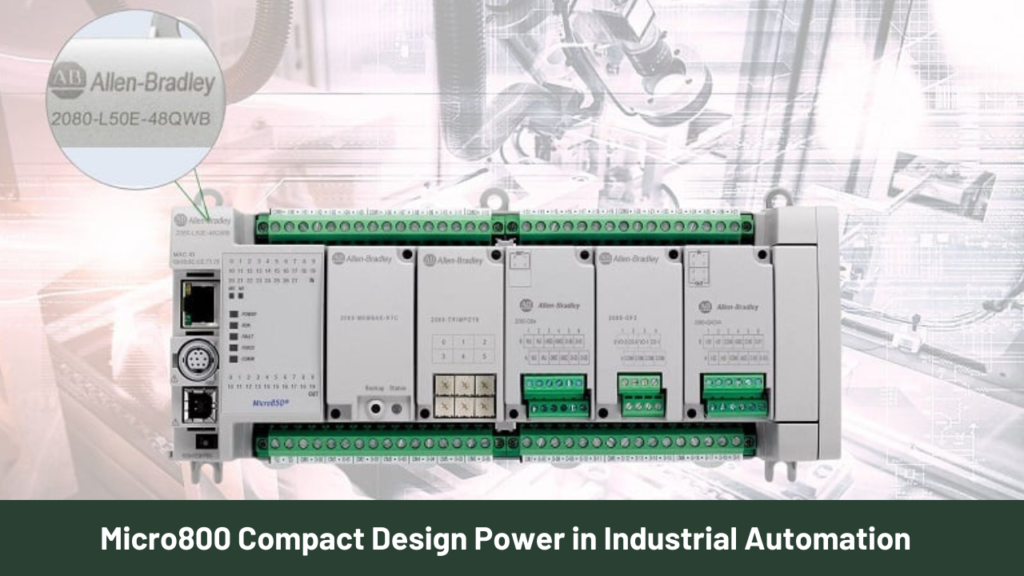

In the intricate realm of industrial automation, space optimization, flexibility, and efficiency are highly valued attributes. Rockwell Automation’s Micro800 PLCs, or programmable logic controllers, are small design powerhouses that have completely changed the control systems market. In this blog article, we’ll look at how the Micro800 series’ compact size and superb capability balance are revolutionizing industrial automation.

Space Efficiency:

The Rockwell Automation Micro800 PLCs are ideal in spaces with limited room due to their small size. Because these controllers offer powerful performance in a small package, they work incredibly well in areas where every square inch matters. This allows for more efficient use of machinery and space management in cabinets.

In industrial environments, every square meter of floor space is precious. Space efficiency is crucial for maximizing production capacity and fitting a range of processes into the available area. Accomplishing this goal requires compact solutions for everything from machinery to control systems.

Cost-Effective Automation:

Despite their small size, Micro800 PLCs fulfill a wide range of automation applications because to their very extensive feature set. Because of their cost, these controllers are a desirable choice for small to medium-sized applications, providing businesses with a robust yet fairly priced solution to their automation demands.

In today’s globalized market, maintaining a competitive edge is crucial for businesses. By using cost-effective automation, businesses may boost productivity, reduce production costs, and provide goods and services more competitively in the market.

Automation may be used to maximize the utilization of labor, time, and materials. By automating repetitive and resource-intensive tasks, businesses may boost productivity and use resources more effectively.

Adaptability and Scalability:

One important design factor for Micro800 PLCs is adaptability. Because controllers are scalable, users can choose them based on the specific needs of their applications. Its remarkable versatility allows it to be easily incorporated into a variety of industrial applications, ranging from standalone machines to more complex automation systems.

The rapid advancement of technology has led to the creation of new tools and solutions. Systems for adaptive automation make it easier to incorporate new technologies into an existing business without causing major disruptions to operations. This allows businesses to stay inventive.

various applications within an industry may require various things. Customization is achievable and several programs may be installed for a single system with adaptive automation, all without the need for extensive overhauls or reprogramming.

Integrated I/O:

One of the special advantages of Allen Bradley Micro800 PLCs is their direct input/output (I/O) integration. This integrated approach reduces total control system complexity and streamlines wiring, enabling speedier installation and maintenance operations.

Integrated I/O streamlines connectivity by reducing the number of wires and connections required in a control system. This not only simplifies installation but also lowers potential failure locations and boosts overall system dependability.

Consolidating I/O chores into the PLC frees up a significant amount of room for control cabinets. Additionally, by eliminating the need for external I/O modules, businesses may save costs associated with purchasing, installing, and maintaining additional hardware components.

Applications of Micro800 Compact Design:

Small-Scale Manufacturing:

Micro800 PLCs work especially well in industries where floor space is limited, such as small-scale manufacturing environments. Their compact design allows for efficient control and automation of processes without compromising performance, making them the ideal choice for maximizing space in production settings.

OEM Machinery:

Original Equipment Manufacturers (OEMs) benefit from the compact architecture of Micro800 PLCs while creating and producing machinery. The controllers may be readily integrated into the confined confines of equipment, providing trustworthy control solutions without using significant space.

Material Handling Systems:

Material handling systems employ Micro800 PLCs because they need compact, high-performance controllers. Whether they are utilized in packaging equipment, conveyor belts, or sorting systems, these controllers are great at making the most of the available space while ensuring precise control and automation.

Stand-Alone Machines:

The Micro800 series is a suitable option for isolated machinery that requires a small yet capable controller. These PLCs offer the perfect balance between capacity and size for a range of uses, from routine industrial tasks to specialized responsibilities.

One example of how innovative little design may be in the world of industrial automation is the Micro800 series. Micro800 PLCs’ small size, low cost, and adaptability are revolutionizing the automation industry. They provide businesses with the tools to make the most of their available space, increase output, and stay competitive in an ever-evolving industrial setting. The Micro800 series is anticipated to have a major impact on industrial automation in the future as businesses continue to realize the advantages of compact design.